Different Types of Printing Methods

for Packaging: A Comprehensive Exploration

Choose a cost-effective and suitable printing technique that increases the charm of your valuable products. Through this ultimate guide, you will be able to make a great decision by choosing the right and perfect printing technique. Read on to learn how printing innovation saves your time and cost.

When we think about packaging the first thing came to our mind is its look. So, choosing the best printing types goes a long way in the packaging industry. With the advent of technology and creative ideas, it not only increases the possibilities for packages and boxes but each method of packaging brings its unique feature to the table. In this blog, we are going to discuss the various types of printing, and their applications while at the same time its pros and cons, but keeping in mind the brand owner’s questions raised concerning the package details.

The Art Of Packaging: An Overview

Whenever we want to order or gift something to someone, the one thing that stands out is the way it is packed or presented. Custom boxes and printing go side by side with the brand. The packaging can be considered the silent and pivotal partner to package. The printing on the package goes from delicate designs to bold ones.

Different Types Of Printing Techniques

1. Lithography

It is of lithographic origin with high quality and multiple applications which consists of four color systems that result in the perfect choice for industries, cosmetics, and electronics. The results would be in a smooth gradient of color and give options to its users.

Pros of Lithography

- Best for retail boxes of products.

- High-quality printing.

- Smooth color gradients.

- Offers a variety of coatings like matte and glossy.

Cons of Lithography

- Limited effectiveness on non-flat surfaces.

- Requires tooling investments for custom printing plates.

- Longer lead times for production.

- More suitable for high-volume printing.

2. Flexography

It is considered a modern method of custom box printing. It is also known as letter printing which is used to print newspapers or to label packages. It can be used on metals, papers, and plastics, making it more useful in the printing industry and more feasible to be used by the industries. It is also cost-effective if a large number of orders are laced at the same time.

Pros of Flexography

- Cost-effective for large-volume orders.

- Low tooling cost as compared to offset.

- Utilizes both water and oil-based inks.

Cons of Flexography

- Slightly lower printing quality than lithography.

- Challenges in replicating photo quality images.

- Limited coating options.

3. Digital Printing

With the growing technologies in the world, digital printing emerging as the life-changing printing method for industries. It can be used with a minimal amount of equipment and materials. Moreover, it can reproduce the products in smaller quantities with minimum effort. It can be considered as the best choice for the small-scale industries.

Pros of Digital Printing

- Minimum tools were needed.

- Quick printing and delivery.

- Suitable for small formats and quantities.

Cons of Digital Printing

- Costs increased with a large number of orders.

- Challenges in matching the colors.

- Limited coating options as compared to lithography.

4. Silkscreen Printing

This technique uses a clothing mesh. The ink is spread on the mesh cloth and the image is printed on boxes. It is used for detail work but can print only a small number of orders in a short period.

Pros of Silkscreen Printing

- Excellent for promotional items.

- Does not require a flat surface for printing.

- Ideal for smaller volumes.

Cons of Silkscreen Printing

- Slower production as compared to other methods.

- Challenges in replicating the photo quality images.

- Not suitable for high-volume production.

5. Rotogravure

This method is used to print larger surfaces which require a lot of ink to enhance their quality. It can replicate fine art and high-quality photos for commercial use such as magazines and cardboard printing.

Pros of Rotogravure

- Offers premium quality images.

- Ideal for high-volume printing without compromising image quality.

Cons of Rotogravure

- Lack of coating options.

- High investment in tooling.

- Longer lead times for production.

6. Thermography Printing

This method is used to engrave the alphabets or images on the surface. It uses offset printing with resin to give a shiny look to the custom printed boxes surface.

Pros of Thermography Printing

- Raised printing value.

- Cost-effective.

- Provides a professional look.

Cons of Thermography Printing

- Raised ink may crack when folded.

- Requires investment in heating tunnel setup.

- May not be eco-friendly due to heat production.

7. Letterpress Printing

This method uses the technique to enhance the quality of printing packages. In the past, this technique only be used to print books and small-scale projects but now it adds beauty to business cards and packages.

Pros of Letterpress Printing

- Ideal for business cards and invitations.

- Produces clean lines and bold images.

- Suited for printing on paper and cardboard.

Cons of Letterpress Printing

- A relatively slow process.

- Time-consuming.

- Photo and drawing conversion may require engraving.

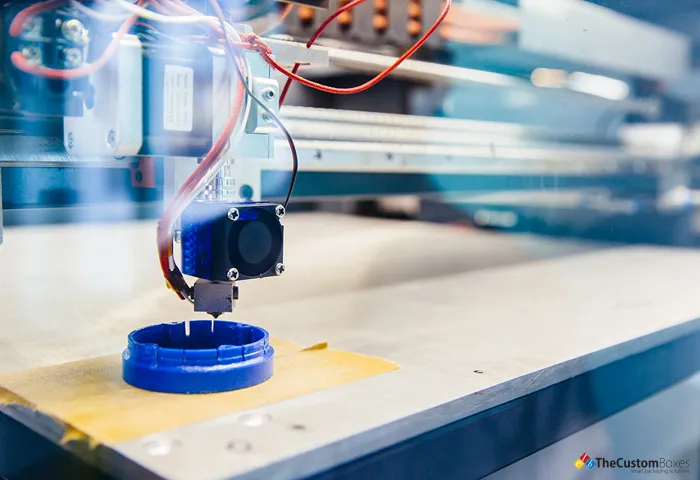

Innovations in Printing Technology: The Rise of 3D Printing

With increasing in advancements technology, three-dimensional (3D) emerges as the new tool for box printing companies. Which not only enhances its uses but also leaves two-dimensional printing behind. This method can be used to print landscapes, toy figurines, and promotional 3D models. It increases the creativity of package industries.

Applications of 3D Printing in Packaging

1. Customized Product Packaging: Tailored to Perfection

One of the most remarkable uses of 3D custom box printing is its capacity to produce unique packaging solutions that are suited to the precise measurements and forms of individual products. This degree of personalization guarantees a secure fit, improving the presentation and safeguarding the contents within. Using this technology, brands may create packaging that appeals to their target market and embodies their brand.

2. Brand Personalization

Different brands use 3D printing to customize their packaging. It includes adding logos, images, or texts. This helps the brands to increase their sales and also creates awareness related to the brand to their buyers.

3. Prototyping for New Packaging Designs: Rapid Prototyping

In this era of technology, when the world is changing and adapting to new environments, 3D printing technology can be used as a new prototyping tool for packaging. With the advent of 3D use in the packaging industry, designers and manufacturers use this technology to modify concepts and refine their ideas to get the product without the use of extensive work or tools.

4. Cost-Efficient Design Validation

Using the traditional methods for custom print on boxes, 3D printing is cost-effective and takes less time than the other printing methods. It streamlines the printing process with rapid validation and affordability. At the same time enhancing creativity, innovation, and productivity in package designing.

5. Unique Promotional Items with Intricate Details: Elevating Brand Merchandise

The use of 3D printing not only increases production in the industries but at the same time, this process helps in advertisement. Production of 3D models, keychains, or figurines, not only attracts the buyers but also shows their creativity and their dedication towards originality.

6. Detailed and Complex Shapes

In contrast to conventional production techniques, 3D printing works exceptionally well at creating objects with exquisite details and complex shapes. This creates new opportunities for creating unique promotional products that draw customers in and strengthen brand identity.

7. Sustainable Packaging Solutions: Reduced Material Waste

3D printing & packaging also helps to reduce waste product production in the environment. As the world is moving toward conserving the earth and its resources, 3D printing in packaging plays an important role. The brands are producing biodegradable packaging or eco-friendly forms which not only reduces waste but also increases awareness.

8. On-Demand Production

It facilitates the production of on-demand packaging without increasing the cost. 3D printing not only decreases the time of product but also uses minimum tools and time to produce the packaging.

9. Enhanced Security Features: Incorporating Security Elements

Security measures are strengthened by the capability of 3D packaging and printing to directly incorporate features into the packaging structure. Brands can incorporate unique identifiers, QR codes, or even anti-counterfeiting elements directly into the packaging, ensuring product authenticity and bolstering consumer trust.

10. Tamper-Proof Solutions

3D printing allows for the creation of tamper-proof packaging solutions. Intricate seals and closures can be designed and integrated to provide visible evidence of tampering, enhancing product safety and consumer confidence.

11. Interactive Packaging Experiences: Augmented Reality Integration

3D printing when combined with augmented reality (AR), opens up ideas and creativity in the packaging industry. These AR-created logos help the consumers with greater content and product information and at the same time increase the experience between brands and buyers.

12. QR Code Embedding

With this new technology of QR codes when mixed with logos, it not only creates physical connectivity but also digital ones. Buyers can easily access the brans through this QR code scan and get instant information which indeed increased the creativity in the printing industry of packaging.

13. Challenges in 3D Printing

- Material limitations for food and pharmaceutical packaging.

- Longer production times compared to traditional methods.

- Initial setup costs for 3D printing equipment.

Exciting Possibilities with 3D Printing

Customized Product Packaging

Packaging that is highly personalized and meticulously crafted to fit certain products can be created thanks to 3D printing. Nowadays, brands can look into different box design ideas that precisely fits the curves of their products, giving them a tight and attractive look. This degree of personalization makes the unboxing experience more enjoyable for customers and fosters a lasting relationship with the brand.

Prototyping for New Packaging Designs

Packaging development's design and testing phase is revolutionized by 3D printing's quick prototype capabilities. Physical prototypes may be swiftly produced by manufacturers and designers, enabling an in-person assessment of the shape, fit, and functionality of the packaging. Iterative design cycles shorten the time it takes for new items to reach the market.

Unique Promotional Items with Intricate Details

Beyond traditional packaging, 3D printing opens up avenues for creating unique and eye-catching promotional items. Brands can design promotional merchandise with intricate details and complex structures that were once challenging or impossible to achieve through traditional manufacturing methods. This uniqueness not only serves as effective marketing but also fosters a sense of exclusivity.

Enhanced Brand Personalization

Personalization is a key trend in today's consumer landscape and 3D printing allows brands to take it to the next level. Packaging can be personalized not only with names and messages but also with 3D elements that reflect the individuality of each consumer. This level of personalization fosters a deeper connection between the brand and its customers.

Intricate Geometric Patterns and Textures

The precision of 3D printing technology enables the incorporation of intricate geometric patterns and textures into packaging designs. A sophisticated lattice structure on the packaging of a tech device or a delicate texture on a cosmetic box—intricate design concepts that grab the attention of consumers can be realized thanks to 3D printing.

Functional Packaging Elements

3D printing extends beyond aesthetics to introduce functional elements within the packaging. This includes features such as built-in handles, hinges, or closures that seamlessly integrate into the design. The result is not just visually appealing packaging but also packaging that enhances the overall usability and convenience for the end user.

Sustainable Packaging Solutions

As sustainability becomes a focal point in packaging design, 3D printing offers the potential for more eco-friendly solutions. The ability to precisely control the amount of material used in the printing process reduces waste. Additionally, the exploration of alternative and biodegradable printing materials contributes to environmentally conscious packaging practices.

Interactive Augmented Reality Packaging

3D printing can be seamlessly integrated with augmented reality (AR) technologies to create interactive packaging experiences. Through the use of smartphone apps, brands can incorporate augmented reality (AR) markers or features onto 3D-printed packaging, enabling customers to interact with extra content or virtual aspects and improving their entire brand experience.

Intricate Cutouts and Hollow Structures

The ability to create complex cuts and hollow structures within the packaging is made possible by the layer-by-layer nature of 3D printing. This gives the design a higher level of intricacy and lets light play a part in emphasizing particular elements. The way light and shadow interact to produce visually striking effects enhances the overall aesthetics.

Nanography

Known as a near-future printing technique, nanography produces incredibly tiny features on printed surfaces by combining state-of-the-art printing technology with powdered nanoparticles. It enhances the packaging details and is fast and environmentally friendly, using less ink.

Applications of Nanographic Printing

1. Packaging with Precision

Packaging applications that require a high degree of precision and attention to detail are a good fit for nano-graphic printing. Because it can faithfully replicate complex designs, it's the perfect option for high-end packaging, cosmetics, and other sectors where aesthetics are crucial.

2. High-Volume Commercial Printing

Because of its speed and quality, nano-graphic printing is appropriate for commercial printing applications that require large volumes of output. This applies to brochures, promotional products, and advertising materials where excellent print quality and speedy turnaround times are crucial.

3. Labels and Flexible Packaging

Nano-graphic printing is versatile enough to be used for labels and flexible packaging. Because of its versatility with diverse substrates, labels with vivid colors and detailed details can be made, which helps differentiate shelf-ready and retail-ready products.

4. Photographic and Fine Art Printing

For printing fine art and photographs, nano-graphic printing is an appealing option because of its accuracy and precision in color. High-quality reproductions are sought by those who appreciate the outstanding detail and fidelity with which artists and photographers can copy their work.

Pros of Nanography

- Reduced consumption of ink.

- Increased printing speeds.

- Printing quality enhanced with details

Cons of Nanograph

- Increased investment to start the process

- Decreased in supply rate of printing ink.

Answering the Questions

Which Printing Method Is Considered More Effective For Package Printing?

Making the best printing choice for packaging is a difficult choice that is influenced by several variables. With its classic elegance, offset printing frequently sticks out for its excellent outcomes and broad range of uses. Nonetheless, the type of product, intended market, and brand identity all affect efficacy. Offset printing is still a solid option for goods requiring superior finishing. On the other hand, digital printing works well for some applications because it can meet the need for short print runs and rapid turnaround times.

What Are The Most Common Methods Of Printing In Packaging?

Offset printing, flexography, and digital printing are the three printing techniques most frequently employed in packaging. Every technique has special qualities and uses that meet various demands in the packaging sector. For retail sectors, offset printing produces excellent results, whereas flexography is more cost-effective when producing huge quantities of work. Short runs and small forms are catered to by digital printing because of its short turnaround time and low tooling cost.

What Is Considered The Most Advanced Technology For Printing?

3D printing is currently one of the most sophisticated printing methods available. Its capacity to produce three-dimensional things with minute features creates new opportunities for customization and package design. While offset and digital printing are still widely used, 3D printing is a cutting-edge technique with intriguing promise. Another intriguing technology for the future is nanography, which promises high-quality, fast printing with less of an adverse effect on the environment.

How Many Available Forms Of Printing Are There?

The printing industry is broad and varied, including a range of techniques like letterpress printing, rotogravure printing, digital printing, offset printing, flexography, and silkscreen printing. Every kind meets particular needs and gives designers and brand owners a range of options. The choices are as diverse as the goods they adorn, ranging from the timeless beauty of letterpress to the cutting-edge appeal of digital printing.