Types of Coating Used For

Packaging

Companies who want to increase their client number always make wise decisions. One such strategic move is the use of durable and attractive packaging. It is necessary to protect goods and grab customers' attention. For this, the use of coating is an ideal option that can address both aspects simultaneously. A question arises here: among a variety of available options, which coating should be used? To get the answer read on to explore different types of coating used for diverse kinds of packaging boxes.

The product packaging is as important as the product itself. It is a crucial aspect because it contributes to the safety of a product. Brands work hard to make products and adopt various strategies in their production. Likewise, they wisely focus on practical packaging designs to protect their creations. Thus, they opt for different types of boxes for packaging. Of course, it's paramount as packaging acts as the first line of defense. So, selecting methods to enhance the durability of these packaging solutions is essential. Different types of packaging coatings help to make visually attractive and stronger boxes.

Packaging coatings are special types of coatings that are applied to packaging solutions to enhance their appeal and functionality. There are countless choices for standard and specialty finishes and coatings accessible these days for packaging container designs. It can be fraught for new businesses to choose the appropriate surface finish for their product packaging boxes. Fortunately, after reading this article, you can find the best option for coating and finishing your boxes. It will be according to your packaging specifications.

Some Common And Important Types Of Coating Used For Packaging:

Don’t you know the importance of different types of coatings? They can change the visual appearance of boxes and set them apart from others. If you ask how many types of coating there are, then the answer would be too long. This is because there are several types. However, the commonly used three types of coating are protective coating, decorative coating, and functional coating.

Below are some types of coating for different types of packaging boxes. The purpose of each type is to enhance the durability and elevate the appearance.

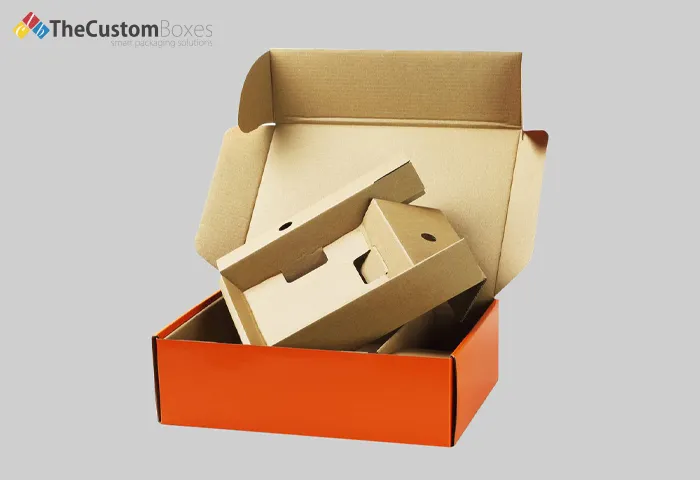

Corrugated Packaging Boxes:

Corrugated boxes are extensively used for delivery and e-commerce packing due to their denser and more durable material. These are the most robust types of boxes packaging. Following are some important types of coatings for cardboard corrugated boxes.

Lamination:

A plastic-coated covering offers your box the definitive fortification of your illustration. Only well-reputed companies practice lamination on their delivery containers. They practice it as a source to make the most of their sculpture presence which digital reproduction cannot do. Laminated cardboard boxes possess a spark that helps to enthrall the viewers. The single drawback with gloss coating or UV coating is that the wrinkles of the boxes become more noticeable.

Gloss Varnish:

Mainly for small to medium enterprises, gloss varnish is the superior choice. Digital printing for wrapping is usually used to facilitate small to average-sized tasks for corrugated containers. It will help to raise manufacturing proficiency, produce a quicker reversal time, and, obviously, lower unit cost. These containers are generally for carriage and shipping; superfluities on the packing and luxurious covering are usually not mandatory. Companies are becoming further motivated to enhance design components to their delivery packages to influence promotion prospects.

Furthermore, the firmness of the corrugated material is sufficient to safeguard the packaged merchandise. There may be no need for supplementary covering. It depends on the complication or simplicity of your shades and sculpture. You can still yield a first-class packing container with a little gloss varnish or no covering of any kind.

Paperboard Packaging Boxes:

Paperboard boxes are one of the most common types of boxes used for packaging. Paperboard material is extensively popular for its elasticity and adaptability. It is typically accustomed to showcasing merchandise in wholesale stores. Originators are inclined to be more imaginative through finishing and receiving the attraction on the shelves.

Lamination:

Laminated paper boxes wholesale are deliberated to have top quality but are characteristically extra costly due to their shielding characteristics. In comparison to other covering categories, lamination delivers the best fortification from wetness. Long-term ventures also usually favor using lamination owing to its dust resistance and durability. An additional benefit of lamination is its drawing productivity. Luxury merchandise is inclined to select matte lamination to accomplish a smooth appearance. They practice gloss lamination to attain a vibrant and outstanding look. Paper boxes with this type of coating are commonly available. Credit goes to its enhanced practicality and up-to-the-mark visual appeal.

UV & AQ Finishing:

If you are seeking a less costly choice, you must consider a small gloss AQ coating. In the meantime, AQ is aquatic-based; ultimate AQ coverings can be measured as food-safe. That is why you can use AQ coating on food containers. AQ is broadly acknowledged as the default of all coatings because of its low price and high efficiency. It offers a low gloss polish that provides a bit of roughness to the containers. But it does not provide roughness excessively, and it diverts the appreciation. Ultraviolet Coatings or UV coating alternatively produce a glossy presence just like gloss lamination. Thus, it works amazingly well in grabbing attention.

Luxury Packaging:

Among different styles of packaging, luxury packaging always stands tall. Using rigid boxes with coatings is the easiest way to exude luxury. Moreover, straightforwardness, minimalism, extravagant, and luxurious look are the common characteristics of rigid box packing. Hence, matte lamination is the most exceptional choice for this kind of packaging.

Matte Lamination:

Matte lamination is the suggested covering for luxury packages. The presence of this specific finishing is extensively important for its stylishness and class. It is the best coating to utilize once you integrate distinctive procedures into your packages. For instance, beautification of foil imprinting and spot UV is a good idea.

Metallic Coating:

If you are searching what are the types of coating that add elevated shine then metallic coating is your answer. With this type of coating, you can turn a simple box into a lustrous one. Metalized rigid boxes are the best choice for brands that sell premium products. These products may include expensive perfumes, watches, jewelry items, and many more. Packing such items in these boxes is a good approach. The reason is they can protect them better against external factors. Moreover, they add value to the product, increasing perception. It can significantly impact consumer purchasing decisions.

Specialty Coating:

Do you have plenty of budget to capitalize on your packing scheme? If yes, it necessitates more distinctive features that you can also choose for extraordinary coatings. These sorts of coverings are important for longer tasks. It is because of their additional expenditures. Though, if the financial plan is not an issue, you should go with it. Here are some specialty coatings which can enhance the beauty of your products. These options include embossed and debossed, a Pearlized layer, Scented, Glittered, Foil Stamped, and textured paper coatings.

Selecting the paramount coating for your merchandise’s container packing certainly necessitates your time and consideration. You have to study and carry on to a conversation with your producer. It should help to bargain the appropriate coating or varnishing for your container. Keep in mind; that a fine-arranged strategy for your packing will make your life much more relaxed. Having a firm idea about your product, your goals, and your financial plan should be on priority. From here, you can obligate an improved intellect of inclusive packing. It will comprise the covering and supplementary finishing that is the best solution for your packaging problems. Making the appropriate decision about the coating or varnishing of your packaging product will enhance your productivity and profitability. This is because more customers will love to buy your products.

What Are The Common Coating Materials?

If you want to know the answer to the above question then continue reading. Although it is not easy to narrate the list of countless coating materials. However, the common packaging coatings among them are:

- Epoxy

- Silicone

- Latex

- Ceramic

- Polyester

- Acrylic

- Zinc

- Alkyd

- Polyurethane

Each material features characteristic properties and distinctive benefits. The choice is ultimately yours. See which material suits your needs and preferences before finalizing a particular type. For example, go for epoxy if you require strong adhesion and corrosion resistance. For fast drying, use acrylic coatings. Polyurethane coatings are the best because they are durable and offer versatility. Whatever option you select it’s a smart move to check its environmental impact. The ideal approach is to opt for sustainable packaging coatings that do not harm the environment. It's better to prioritize safe coating methods.

Benefits of Adding a Coating:

Considering various coatings for packaging comes with a myriad of benefits. Some of them are:

- Enhance Visual Appeal

When it comes to the selection of product packaging design, all businesses have to make sure that their packaging is outstanding. According to observation, all brands try tooth and nail to enhance the visual appeal of their boxes. Due to different types of coatings, the boxes can get a better and more enticing visual appearance. It is extremely beneficial for a brand because it can improve the brand image. Moreover, there are several ways these boxes can catch the eyes of people and increase the worth of a brand. Hence, people feel special when they get their products in these boxes.

- Entice new Customers

Most brands need custom boxes to attract customers. According to experts, the boxes with custom features can be more effective in driving sales. This is because they can entice a lot of new customers. You should understand that the visual outlook of these boxes is impressive. Therefore, they can grasp the attention of people passing by. Ultimately, they can lead to higher sales and make the business successful.

- Product Safety

Adding coats is good for enhancing product safety. Boxes with coatings are stronger than those without coatings. The additional layer over the box material contributes to robust box construction. As a result, the box can better bear the rigors of handling and storage. Even shipping goods in these boxes is a safer choice. All brands especially e-commerce can avail of this benefit in building a strong customer base.

Final Thoughts:

All brands prioritize the safety of their products. Also, they want means to make a prominent market presence. Different types of product packaging boxes with coating can meet their needs. There are many types of coatings used for packaging. Some of them are already mentioned. Pick the one that aligns with your preferences and product requirements. It is a wise approach to consider their impact on customers and the environment before finalizing a particular coating. Applying coatings on your packaging offers you unlimited benefits. Make a better selection and enjoy more profit by grabbing and satisfying customers.